METAL7

We are Metal7.

Since 1974, Metal7 has been dedicated to the design and manufacture of high-performance process products and equipment. Our quest is to create a significant impact by contributing to the enhanced efficiency of pellet plants, all the while advocating for a more environmentally friendly approach to industrial processes.

Client-Centric Motivation: You are Our Driving Force.

The involvement of our customers in the development of our products is essential. We believe in working closely with our customers to create tailor-made solutions. Their expertise and feedback guide our innovation. We also value the durability of our partnership after equipment installation. We are committed to assisting our customers in the use of our products in an industrial context, solving problems, and providing technical advice for maximum efficiency. We aim to really improve their operations, not just sell products.

Metal7 stands out for its ongoing commitment to innovation, as demonstrated by our patents and patent applications pending worldwide. From Brazil to India to the USA, we have obtained patents such as BR112019014608-3, US11.697.860 and IN478284, demonstrating recognition of our expertise and innovative technologies. In addition, our pending patent applications in Canada (CA3.049.812) and Mexico (MX/A/2019/008578) testify to our commitment to extending our reach and strengthening our position in the international marketplace.

InNovation

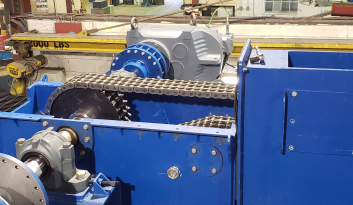

Our Innovation and Engineering teams are made up of engineering experts, technicians, and designers with in-depth knowledge of our customers’ processes. Their mission is to improve existing products, design innovative solutions to optimize the reliability and performance of our customers’ equipment and processes, always in the spirit of sustainability.

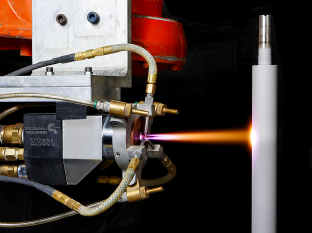

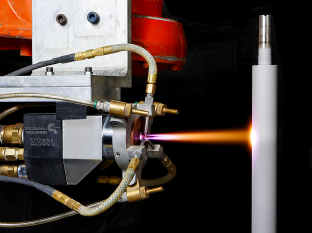

Metal7 excels in surface coating expertise thanks to continuous investment in thermal spray technology over several decades. Today, we are recognized as one of the largest thermal spray operations in North America. This process involves applying metallic, ceramic or cermet materials over a substrate to improve its surface properties, including resistance to wear, corrosion, heat, and chemical attacks. The choice of coating type depends on the surface properties required for optimum performance.

The Innovation and Engineering teams follow a systematic, structured approach to managing new product development. This divides the process into distinct stages with informed decisions at each step, optimizing the chances of success and minimizing risks. For continuous improvement projects, we adopt a Lean Six Sigma approach aimed at improving process quality, reducing costs, increasing operational efficiency, and enhancing customer satisfaction.

Metal7 Product Overview

As a renowned global player in the field of thermal spraying, we integrate this technology into our products to protect critical components. Thanks to this advanced expertise, our business unit sets itself apart from the competition by offering sophisticated, high-performance solutions, thereby strengthening our competitive position on the international market. Our products are used in some 80% of iron ore pelletizing plants on five continents.